A pinch of ruthenium, the Italian way to an economical green hydrogen

Towards a new generation of alkaline electrolyzers

Solar electrolysis and nanostructures of ruthenium, a rare metal, could be the new recipe for cheap green hydrogen. To dose and test the ingredients, a group of researchers from the Italian Institute of Technology (IIT) in Genoa, and BeDimensional SpA, a spin-off of the same IIT. Scientists have developed an essential component of the production of hydrogen by electrolysis: the catalyst, the chemical species added to the reaction to increase its speed.

In the evolution of hydrogen, one of the two reactions that take place in the electrolysis of water, the electrocatalyst able to provide the best results today consists of platinum deposited on the mesoporous carbon. This compound has proven to work excellently with both acid and basic electrolytes used by alkaline electrolytes (market-leading technology). However, it is not a mystery that this element is particularly expensive and that its price, together with that of electricity, affects the final cost of the carrier H2.

To obtain cheap and competitive green hydrogen with its fossil version (the gray H2), explain scientists, “it is essential to design a new generation of sustainable and highly efficient electrocatalysts that can be integrated into electrolysers, able to operate continuously at practical current densities, that is, in the range of 0.2-1 A/cm2 or even higher”.

A new electrocatalyst for green hydrogen

The IIT and BeDimensional team replaced platinum with ruthenium (Ru). Although it is a rare metal, it is currently available at about one-fifth of the price of platinum. But exchanging one element with another represents a complex action in practice. Ru-based catalysts face, in fact, several technical problems, from the strong metal-hydrogen bond that prevents an effective release of H2 to the risk of “poisoning” of the catalyst’s active sites.

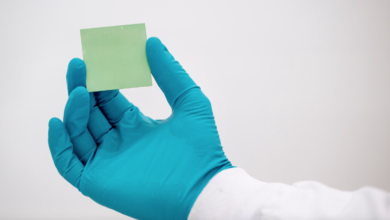

The team overcame these drawbacks by designing an amorphous tio2/copper electrode decorated with tiny ruthenium and copper structures. The new technology requires only 40 milligrams of ruthenium per kW. For comparison in membrane electrolysers, up to 1 gram of platinum per kW is used.

“We carried out the electrochemical analysis, theoretical simulations and tests under industrially relevant conditions that allowed us to determine the catalytic activity of our materials and understand their operation at the molecular level, or the mechanism of the water splitting reaction on their surface”, explain Sebastiano Bellani and Marilena Zappia of BeDimensional involved in the research. “Thanks to the data collected, a techno-economic analysis has also demonstrated the competitiveness of this technology both with hydrogen production methods (based on fossil sources) and with current electrolyzer”.

read also Solar green hydrogen: how to make water photoelectrolysis competitive

The future outlook

Using ruthenium, researchers at IIT and BeDimensional have made it possible to improve alkaline electrolyzers, making this technology more efficient and with long operating life, able to reduce the production costs of green hydrogen. “In the future, we plan to apply our technology, and nanostructured catalysts based on sustainable two-dimensional materials, in large-scale electrolysis plants powered by electricity from renewable sources, including electricity produced by photovoltaic parks”, conclude the researchers. The results of the study were published in the Journal of the American Chemical Society and Nature Communications.