Fungi, organic waste and 3D printing create new biomaterials

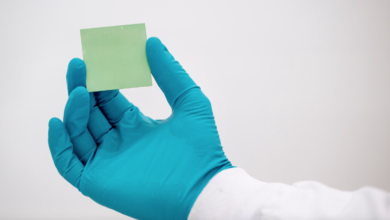

Biomaterials created by the University of Sydney are based on coffee grounds and cardboard fragments, on which to grow mycelium

New biodegradable biomaterials that may be used in a variety of goods can be created through the mushroom cultivation industry. Recent research at the University of Sydney, where a group of scientists created some prototypes based on so-called myco-materials, provided evidence of this.

In the experiment, 3D printing, mushroom culture, and the usage of organic waste—such as coffee grounds and cardboard scraps—are all combined. The secret to the procedure is that fungi may attach to unprocessed organic matter by creating a netting of roots during growth. Mycelium, the vegetative component of fungi, creates the structure known as the mycorrhizal network.

How to make biomaterials?

The mycelium is articulated in an intertwining of filaments called hyphae. This network works as a binder and as a cover for organic waste material used by Australian researchers.

The scientists melted molds of basic objects like spheres, a teapot, and a bunny to test the device’s functionality. They then improved the procedure into more sophisticated and useful initiatives that take advantage of the fungus’ inherent qualities. A flower container with sensors to monitor and report soil conditions was produced using this method in the experiment. Mycelium can also be grown around constructions that include electronic components. When the plant is prepared to transfer to a larger container, the pot also breaks down.

read also Alternatives to plastic: silk protein based biomaterial from MIT

These myco-materials are energy efficient and draw their energy from waste material, be it sawdust, cardboard or coffee grounds. They can be used in a variety of applications, and could be a resource for low-income countries, where problems of cost and access to materials persist.