Ultrasonic technology against microplastics from Japan

Collection rate of 90% achieved for microplastics larger than 5 μm

(sustainabilityenvironment.com) – There is a reason if the microplastics that are polluting every corner of the ocean are so difficult to remove from the water. This is the high cost, in terms of work and money, of the collection and isolation process.

However, that debris, which is less than 5 m in size, poses a significant environmental risk. They are produced by synthetic fibers used in clothing that are released from our washing machines or by the decomposition of plastic debris from wear and sunlight. Personal care products, which include them in the form of microscopic spheres, are another source of microplastics.

Traditionally, water is filtered using a type of sieve to remove microplastics. Plastic is separated from sand and biological contaminants via density separation and chemical processing. The microplastics are then physically removed, which is time-consuming and tedious. Sieves can also quickly become clogged and be unable to capture particles smaller than their nets.

Ultrasound and tunnels against microplastics

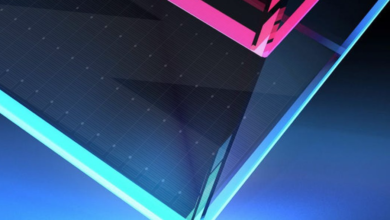

Some scientists have looked for alternatives in light of all these restrictions. The most intriguing comes from a team of researchers under the direction of Professor Yoshitake Akiyama from the Faculty of Textile Sciences and Technologies at Shinshu University in Japan. They are from the Department of Mechanical and Robotic Engineering. The group created a specific kind of microfluidic device, which is a device that transfers tiny volumes of fluid through channels with a diameter of a micrometer. Acoustic focusing is used by this kind of apparatus to gather microplastics.

How does it work? Acoustic technology generates ultrasonic waves that transport microplastics to the center of the fluid flow passing through the tiny channels. This operation increases the collection, because it prevents the debris from floating randomly in the water, concentrating them in a precise point. The problem with traditional devices is that you have to pass water and debris through the canal several times. So, the researchers tried – successfully – to speed up operations, using a microfluidic device that from the central stem branches off into three channels. Through the first, the sound wave concentrates all the plastic, while in the two lateral discharges the fluid that accompanies it.

Read also 60 years and not feel them: the microplastics on the seabed of the Mediterranean are eternal

There are multiple tripartite junctions, and at each one an increasing concentration of microplastics is produced by the gradual fluid ejection. Overall, you can multiply the collection by more than 100 thanks to this. The collection quality is also good, demonstrating the effectiveness of these “sieves“: the rate exceeds 90% for all microparticles larger than 5 m, which are too small to be controlled by sound waves. For those, new tactics will need to be developed, while disregarding the numerous doable things that may be done upstream of the chain to stop the manufacturing. There is now an additional fix for all the others.