Thermal insulation: smart material which changes color under an external electrical stimulus

According to researchers, a very small amount of energy is enough to trigger the change

(sustainabilityenvironment.com) – Imagine being able to change “dress” to your home, dressing it in black in winter to attract as much heat as possible. And dress her in white in the summer to reflect the sun’s rays. Researchers at the Pritzker School of Molecular Engineering (PME) at the University of Chicago have turned the dream into reality. The secret of the project is an intelligent electrochromic material, able to change color depending on the needs to optimize the thermal insulation.

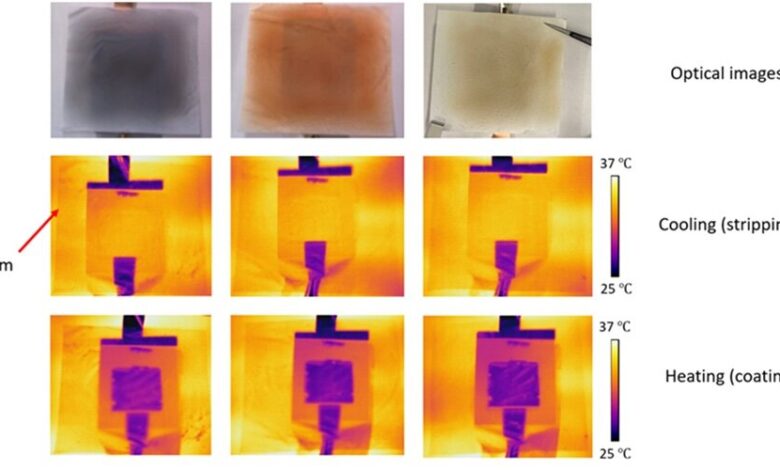

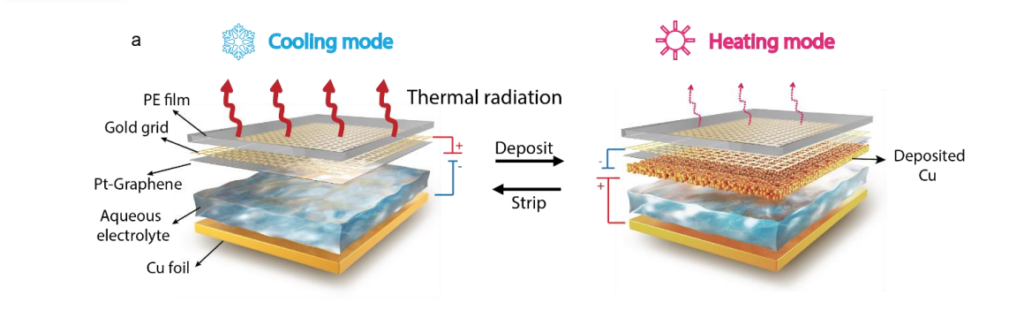

On hot days the material can emit up to 92% of the infrared heat it contains. While on colder days the heat is retained inside reducing the infrared emission to only 7%.

“We’ve essentially figured out a low-energy way to treat a building like a person; you add a layer when you’re cold and take off a layer when you’re hot,” said stressed Prof. Po-Chun Hsu, head of research published in Nature Sustainability. “This kind of smart material lets us maintain the temperature in a building without huge amounts of energy.“

Which material is typically used as a thermal insulator?

The urgency of finding a solution to the incredible amount of emissions and energy waste that the construction world is still responsible for today is pushing scientists towards increasingly innovative technologies. Furthermore, climate change has triggered extreme phenomena that we were not used to by swinging the thermometer from the highest peaks to the lowest. The watchword is therefore resilience, identifying constructive solutions capable of adapting to changing external weather conditions. Maximize the thermal insulate.

Read also The problem of the rebound effect that cancels the benefits of thermal insulation

The chameleon material developed by Professor Hsu’s team seems to have hit the target. The thermal insulation of the building takes place thanks to the change of the outer layer of the material that, with a small amount of energy, is able to assume two different conformations: solid copper when it is necessary to retain infrared heat or an aqueous solution when instead the goal is to emit infrared. Once the temperature at which to change “color” has been identified, a small electrical discharge is enough to modify the outer layer, depositing the copper or removing it according to the needs.

Moving from theory to practice

The smart material was tested by researchers in 15 different case studies across the United States, applying elements about 6 centimeters in diameter at different points in the building. After well 1,800 cycles of transformation from one layer to another, the efficiency of this unusual building material has remained unchanged while ensuring excellent thermal insulation.

The next step will be to find the easiest way to manufacture the material and then use it in building projects.

“We are continuing to work with engineers and the construction industry to examine how this solution can contribute to a more sustainable future,” Hsu concluded.