Double-sided solar cells in CIGS, a new promise

The first double-sided solar cells in CIGS with high efficiencies

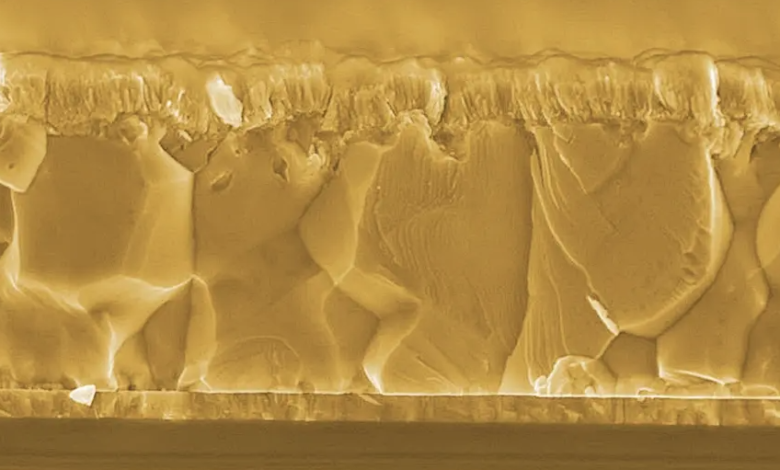

If you have ever heard of double-sided photovoltaics, you will also know that the industry standard strictly employs crystalline silicon. A choice dictated not only by the familiarity of the solar industry with this historic semiconductor but also by a series of technical constraints. The research is testing, in fact, also other materials in the “double-sided” design, but the efficiencies obtained so far have been quite disappointing. This is the case of double-sided solar cells in CIGS, that is (di)seleniur copper indium gallium. This semiconductor is already used as an adsorbent material in thin film photovoltaics, has carved out a niche in the market and has reached light-electricity conversion peaks of 22% (EMPA record of 2022). Too bad that, once inserted in a double-sided design, the values are lowered drastically instead of increasing.

To understand the problem we need to take a few steps back.

In order for a double-sided photovoltaic cell to be able to collect reflected sunlight on the back side, an optically transparent electrical contact must be introduced into the architecture. This is achieved by using a transparent conductive oxide that replaces the matte molybdenum rear contact of conventional photovoltaic.

The process by which the thin film is produced in CIGS requires high temperatures (>550 degrees) to interfere with the transparent rear contact. In detail, the heat promotes the formation of a layer of gallium oxide between the semiconductor and the conductive oxide that blocks the flow of current. This is a major problem and one that, until yesterday, has held back hopes in this segment. The highest values achieved in the double-sided solar cell in CIGS were, in fact, 9.0% for the front and 7.1% for the back.

Today, a group of researchers from EMPA, the Swiss Federal Laboratories for Materials Science and Technology, have overcome the obstacle. Scientists have developed a low-temperature process that can reduce the production of gallium oxide. The secret? Employ a small amount of silver to lower the melting point of the CIGS alloy but still get absorbent layers with good electronic properties. Cell tests showed record efficiencies of 19.8% for front lighting and 10.9% for rear lighting. Showing no gallium oxide formation. The values have been independently certified by the Fraunhofer Institute for Solar Energy Systems. The team went even further by creating a tandem double-sided solar cell in CIGS and perovskite and today aims for efficiencies above 33%.