From AquiPor recycled bricks that filter pollutants from rainwater

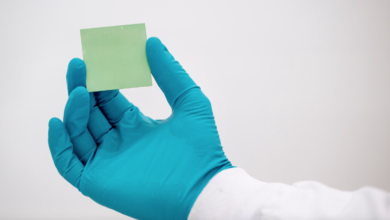

(Sustainabilityenvironment.com) – A new generation of building materials produced by recycling and with low environmental impact. But above all able to give a proactive hand to the environment and reduce the weight of cementification. These are the recycled bricks of AquiPor Technologies, an American startup specializing in “next generation green infrastructure”. The young company develops engineered building materials for stormwater management.

The company’s flagship product is a sort of caleostrzzo obtained from recycled industrial minerals and aggregates, doing without the famous but energivorous Portland cement.

What is his strength? The high level of porosity on the nanometer scale makes it permeable to water, together with the hardness, which makes it an excellent walking surface. “The compressive strength of our material varies from 8,000 to 10,000 PSI and will be suitable for vehicular loads,” the company explains. AquiPor technology allows large amounts of water to pass through the material, retaining dirt, debris and particulate matter on the surface. The solution thus facilitates subsequent cleaning operations, while avoiding clogging problems in other types of green infrastructure.

Not only that. The technology used for the production of this concrete facilitates the curing time. This means that, in addition to the environmental advantages, production also has better performance: the recycled bricks obtained in the process are removed from the molds after a few hours and do not require, as is usually the case, more days, combining productivity, economic benefits and low environmental impact.

Read also Acorn the curved concrete floor, reusable and removable

Today the company is carrying out research in partnership with a prefabricated concrete producer and has started the first experimental project on a neighborhood scale. “We are moving our products to the testing and certification phase”.