Every year 600 million tons of waste sugar cane bagasse are produced

(sustainabilityenvironment.com) – Experts from the University of East London and architecture firm Grimshaw joined forces to make the first bio-building component made from sugar cane waste. Sugarcrete can be a brick, it can be an insulating panel, act as a load-bearing element or simply by infill. It has excellent resistance to stress and is suitable for the construction of floors or roofs. In short, it has the potential to replace any building material, almost totally reducing carbon emissions related to the production of building components.

From bagasse to green cement

Sugar cane is currently one of the largest crops in the world by volume of production with almost 2 billion tons collected each year. But like everything, even sugar cane generates an organic waste is discarded, the bagasse. These 600 million tons of by-products inspired Sugarcrete. The team of UEL and Grimshaw have therefore imagined to transform waste material into a perfect construction component for green building.

Since cement and concrete production are responsible for most of the harmful emissions and energy consumption of the sector every year, the research is focusing its attention on the most innovative and at the same time efficient alternative green solutions.

Sugarcrete was 4 times lighter than traditional bricks and 15-20% less polluting in terms of emissions. Compared to cement, its carbon emissions are even 20 times lower, but its mechanical performance and strength are compared to traditional materials, even exceeding them.

Dry assembly for high performance green building

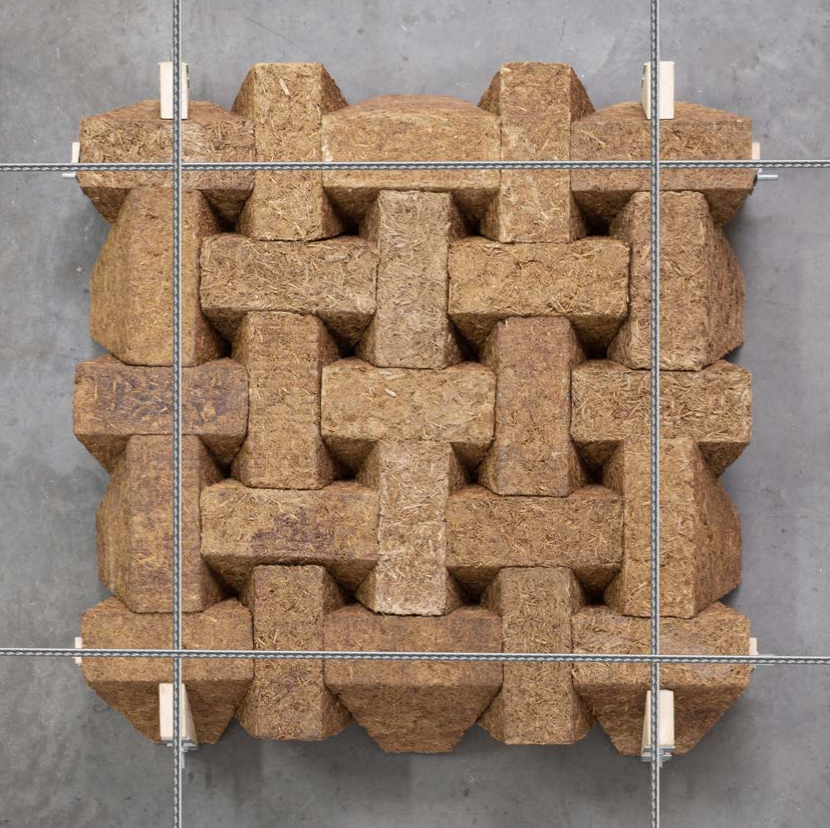

The shape of Sugarcrete is an interlocking polyhedron, connected thanks to post-tension perimeter tie-rods. A dry construction system that reduces the steel content by 90%. Eliminating the steel and assembling the plate with sugarcane fibers at different densities also eliminated the potential cracks typical of concrete. The advantages for the green building of the Sugarcrete system are also obtained in terms of time, not having to wait for the biblical times of hardening of the cls, of resistance to fire and of enduring seismic shocks. It can also be used as thermal insulation of walls and roofs.

“By challenging the misconceptions that waste materials are inferior in structural strength, Sugarcrete can offer self-supporting structural applications in addition to filling,” the project team said.

Using robotic fabrication and augmented reality the blocks are designed to be easily made, built and disassembled by anyone.

Those who could benefit most are the countries of the South of the world sugar cane producers themselves. By recovering a material that would end up in landfills, they can start a green building industry with low carbon emissions, but above all at low costs. In fact, often in these geographical areas, the import of building materials such as bricks or blocks of cement, are one of the higher expenses sometimes even disproportionate to the economic possibilities (In Cuba an import brick costs about 3$ compared to an average salary of 148$).