The first hybrid solar cells manufactured under ambient conditions from a simple silicon wafer

(sustainabilityenvironment.com) – The new ingredient for a photovoltaic easy to produce, low cost and high efficiency? It has a complex and not easy to remember name: poly (3,4-ethylenesitophene) polystyrene sulfonate, better known as PEDOT:PSS. What is it? Of a conductive polymer processable in water and widely used in the field of flexible electronics. And thanks to the work of the University of Kyoto one day could become indispensable in the manufacture of a new generation of hybrid solar cells produced at pressure and at room temperature.

In the laboratories of the university, in fact, a group of chemical engineers has demonstrated the feasibility of creating solar cells heterojunction PEDOT:PSS/ silicon without “special” precautions. “We wanted to avoid producing solar cells under vacuum conditions and with high temperature processes, which require large and expensive equipment and a large amount of time,” explains Katsuaki Tanabe, principal author of the publication on PNAS Nexus.

Hybrid solar cells PEDOT:PSS/Si

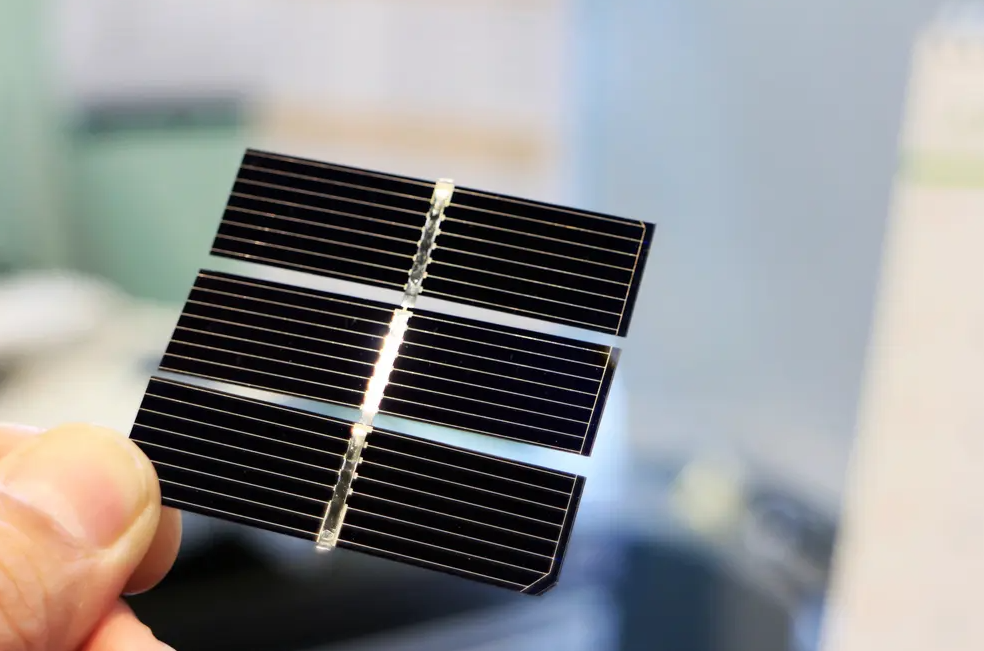

The Tanabe team started directly from the silicon wafer, a thin slice of the semiconductor material with a high degree of purity.

Read also Virtu, the hybrid solar panel for buildings that makes its way to Europe

The group cut the wafer into cubes and cut into 8 mm square pieces, then coated the surface with PEDOT:PSS. The highly transparent and conductive polymer coating acts as a gap transport layer. To complete the hybrid solar cells, scientists used silver ink on the top and back to create the electrodes. All in conditions of temperature and ambient pressure.

“Our approach has allowed us to achieve a better production speed at lower costs and with an energy generation efficiency of more than 10%,” says the author. Although for now the percentage of light conversion appears very low, the research opens the door to a new process of photovoltaic production very efficient. And the work, as the engineers point out, is just beginning. “Next, we will focus on optimizing impurity and additive concentrations in production, as well as other structural innovations”.